Process optimisation of biological treatment

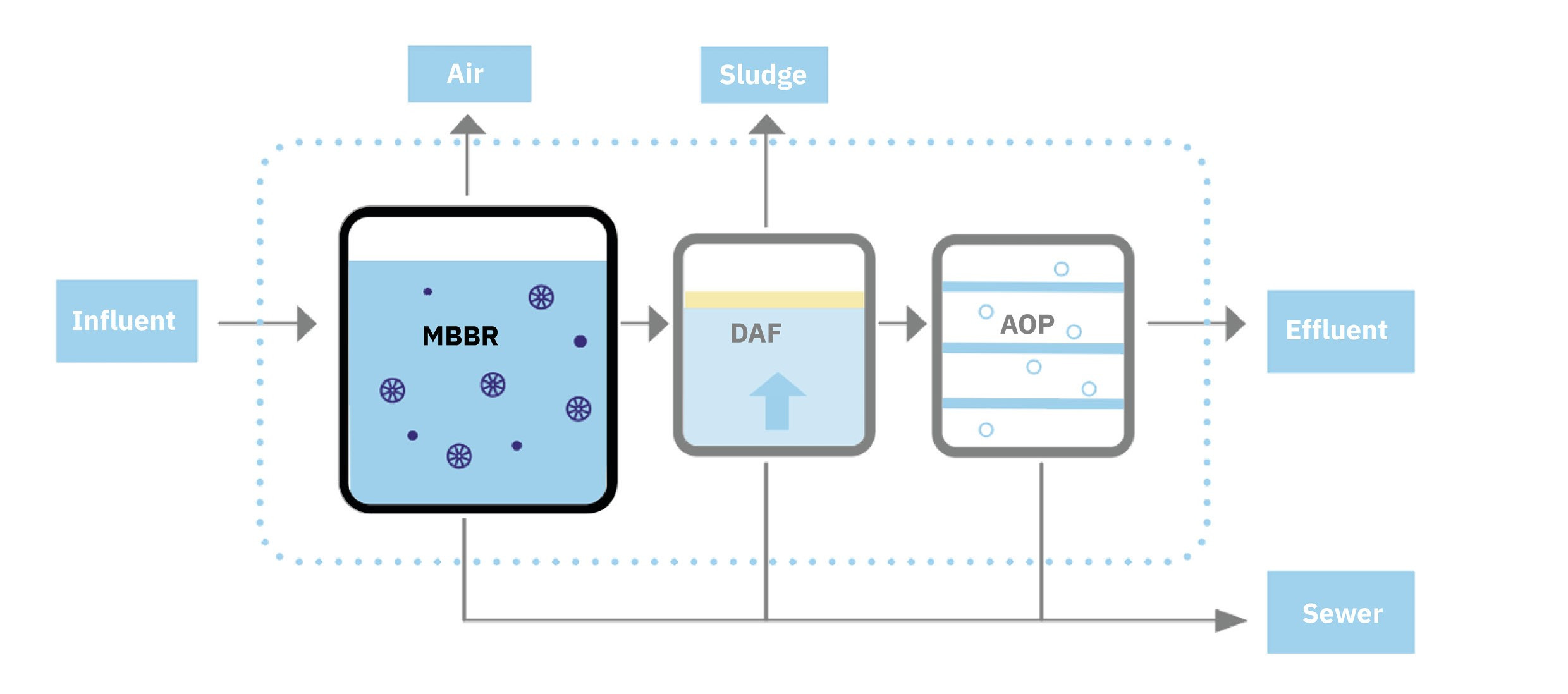

At PureBlue, sustainability is top priority. That is why we opt for biological treatment of wastewater. This is done with the help of bacteria, which grow on small plastic carriers. This process takes place in a Moving Bed Bio Reactor, or MBBR.

On this page, you can read more about our unique MBBR and why our system is so innovative. You will read about the main advantages of this innovation and where it has already been applied.

Moving Bed Bio Reactor

Moving Bed Biofilm Reactor (MBBR) is a well-known biofilm technology. However, the way PureBlue uses this system is quite unique. This is because it is all about process control and process optimisation. One innovative aspect is using the reactor volume as a buffer tank. A second aspect of the innovation is the optimised process control for aeration.

What are the biggest benefits of this innovation?

Wastewater peaks flows due to for example excessive rain events are partially handled by using the reactor volume as a buffer tank, eliminating the need for additional tank volume upfront. In fact, additional tank volume upfront would result in increased load to the MBBR due to hydrolysis of less biodegradable carbon. By using the reactor volume as a buffer tank, carbon which is not available for biological activity is entrapped into the produced sludge and is therefore not 'wasted' by mineralisation to CO2. This also results in a smaller footprint required for the MBBR.

Another innovative aspect is the control for nitrification and denitrification processes through a unique developed aeration regime. Within one tank, it is possible to achieve both carbon and nitrogen removal, which is conventionally done in a two-stage process. Thanks to the optimised process control for aeration, low energy consumption can be achieved. Indeed, aeration is the most energy-intensive aspect when it comes to organic and nitrogen removal processes. PureBlue developed software control is also capable of smartly adapting to load fluctuations.

Examples where this innovation has been applied

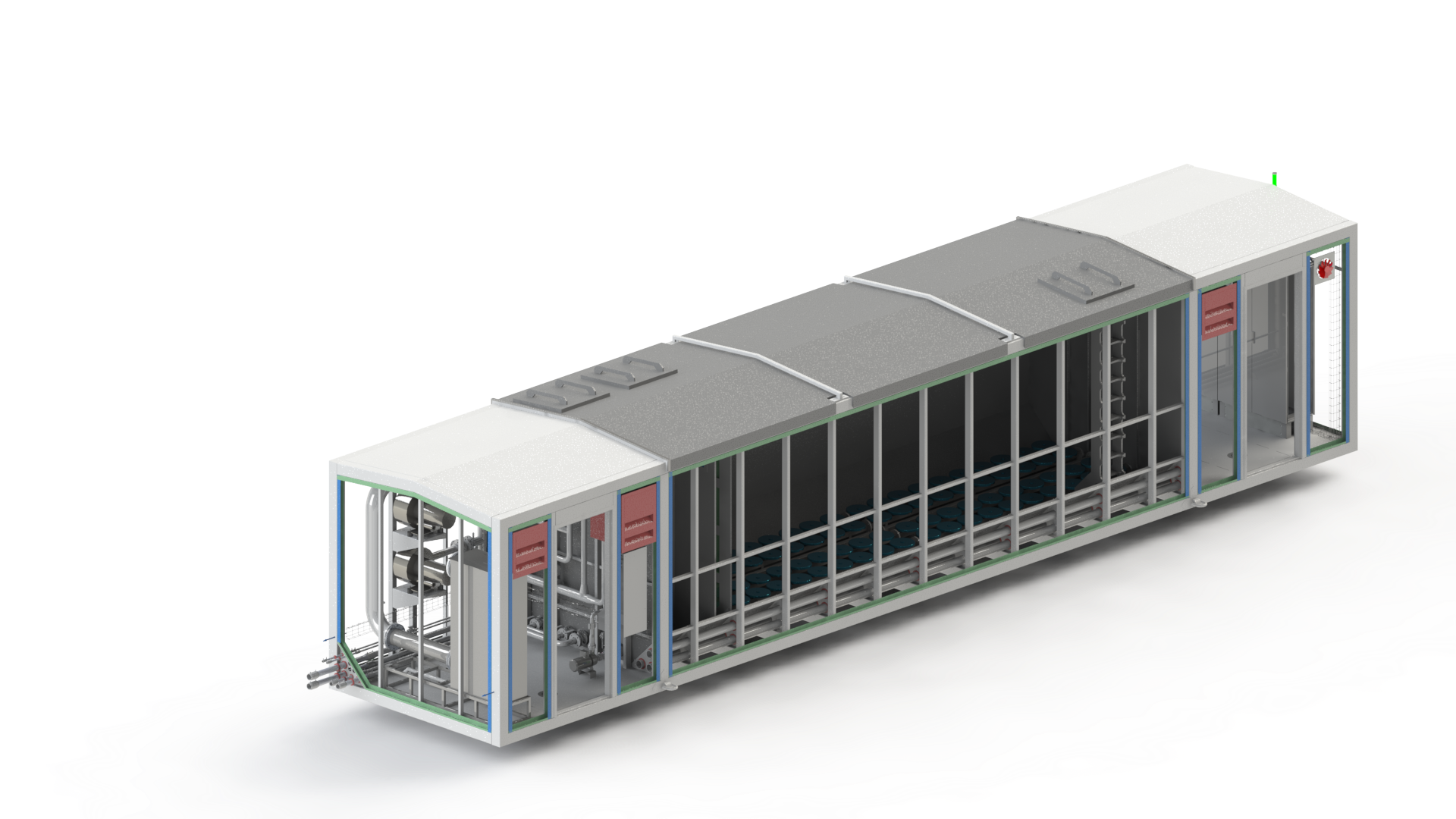

By using the reactor volume as a buffer tank, it is possible to keep the entire system enormously compact. This is important when there is limited space for such an installation. Therefore, this innovation is applied to all InnoPack Marine systems specially designed for river cruise ships.

The optimised process control for aeration is applied in all MicroPack Generation systems. Implementing this process control is very important for recreational areas such as holiday parks. This is because guests are not always present, which means the amount of wastewater can fluctuate. The programme can adapt to these load fluctuations.