Less maintenance of sludge separation

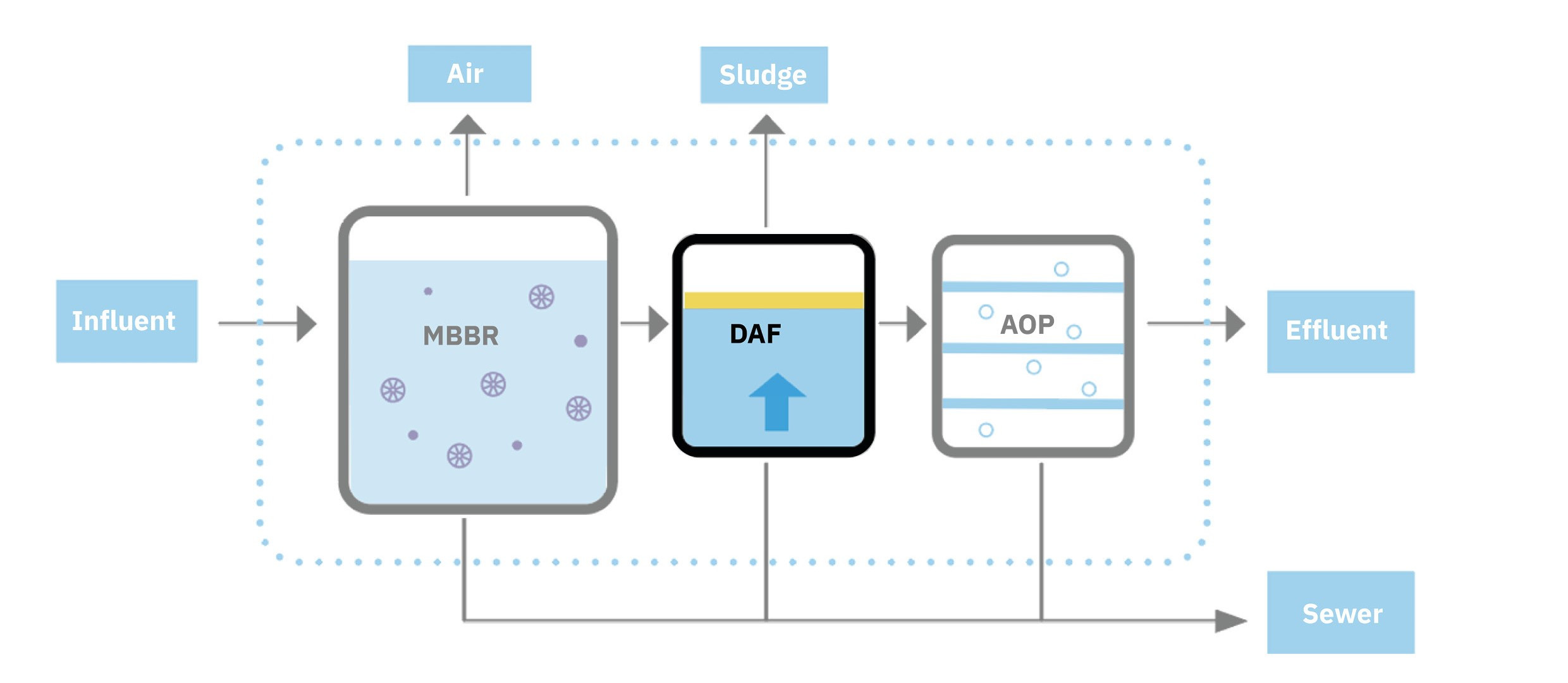

Fine bubbles of dissolved air are used to separate the clean water from the sludge. The tiny bubbles hold the sludge and bring it to the surface, where it is then discharged. We call this process Dissolved Air Flotation.

The sludge that is separated is actually still very valuable. We convert it via a digestion process into new raw materials for the production of green energy, for instance.

Dissolved Air Flotation (DAF)

Our MicroFlux uses DAF technology. This system can remove suspended solids (sludge) from wastewater, for example after biological treatment. At PureBlue, we have developed a smart way to reduce the energy consumption of this sludge separation while optimising the performance of this process.

What are the biggest advantages of this innovation?

A standard DAF system needs a pump and a compressor to recycle the air and bring it into the DAF system. The suspended particles float on top of the water and are mechanically removed by scrapers. PureBlue does it in a different way. We have developed an innovative DAF system without a compressor. All you need is a pump. Suspended particles are removed hydraulically instead of mechanically. This prevents mechanical parts from failing and therefore results in limited maintenance. This keeps component and maintenance costs down. Moreover, the smart process control of our MicroFlux automatically adapts to the different flow rates and loads of the system.

Examples where this innovation has been applied

Our innovative sludge separation is integrated into most PureBlue water treatment systems that treat black or grey water. A good example is the MicroPack Generation, suitable for all kinds of land-based applications like industrial sites, holiday parks, hotels, hospitals and even entire neighbourhoods.